Oil & Gas Industries Fire Detection

Oil and Gas: Protecting Global Power

As the leading energy market, accounting for circa 53% of the global economy, oil and gas is still a huge part of the world’s industry – and as a safety critical environment, Thermocable is proud to play a huge part in minimising the risk of wide-spread fire.

With several associated risks, including highly combustible materials within storage tanks, fires in the oil and gas industry are likely to spread quickly, and create maximum damage – including to buildings and lives in the surrounding areas.

Supplying power to commercial and residential infrastructures, fires in storage tanks can also result in energy loss to hundreds of businesses and communities.

Always recommended to be used in conjunction with a suppression system, linear heat detection cable has various coatings, providing resistance to both chemicals and oil.

Benefits of Linear Heat Detection in the Oil and Gas Market

Cost/Value Benefits

- Low installation costs and minimal maintenance effort versus alternative technologies

- Less labour required to install when compared to spot heat detection

- Cable does not require maintenance

- Will not false alarm in dusty or dirty environments, which prevents emergency service callouts, fines, and wasted time

Functionality Benefits

- Can be positioned directly onto the asset being protected

- Programmable LHD provides a range of alarm temperatures to pick from, with pre-alarm options

- Fixed (digital) LHD technology can identify alarm location at any point along the length of cable from exposure to a tiny flame

Installation/Environmental Benefits

- Range of alarm temperatures available to suit a wide scope of ambient conditions

- Safe to install outdoors or in cold storage/freezers down to -40°C (-40°F)

- High temperature variants suitable for ambient temperatures up to +170°C (338°F)

- Can be subject to differing temperatures along the length of the cable

- Can be installed outdoors in direct sunlight

- Cable coating materials available to offer chemical and oil resistance

- Can resist mechanical abrasion with stainless steel braiding options

Key Applications Within the Oil and Gas Sector

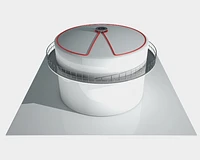

Floating Roof Tanks

Linear heat detection is ideal for early exposure of a fire due to a damaged or worn rim seal on a floating roof tank.

Similarly, lightning strikes may cause fires on floating roof tanks making early warning a necessity. The earlier a fire can be detected on a storage tank containing highly flammable contents, the better chance a suppression system has of preventing a catastrophe.

The addition of a nylon coating on the linear heat detection cable is strongly recommended for maximum protection against environmental conditions.

Fixed Roof Tanks

Tank farms require effective overheat sensing solutions, especially when many tanks are in close proximity to one another.

Linear Heat Detection cable can be used to provide a high level of protection on fixed roof storage tanks. It can be installed close to the points of risks such as vents, flanges or gauging points. By linking the detection system to a fire suppression system, a highly effective fire protection system can be created, minimising the risk of catastrophe.

Nylon coated linear heat detection cable should be chosen to provide the maximum robustness and protection against environmental conditions.

Floating Roof Tanks

ProReact Linear Heat Detection for floating roof tanks.

Protecting critical infrastructure — automatically, reliably, and without compromise.

Fixed Roof Storage Tanks

ProReact Linear Heat Detection for fixed roof storage tanks.

Smart fire detection that protects assets, infrastructure, and lives — automatically.

Download our application guide for more information

(PDF, 708 KB)