Precision Protection for Critical Infrastructure.

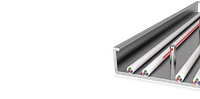

Cable trays are the lifelines of modern infrastructure—housing power, data, and control systems across industrial, commercial, and utility environments. But they’re also vulnerable to overheating, electrical faults, and fire hazards. Dust accumulation, mechanical abrasion, and restricted access make traditional fire detection unreliable and difficult to maintain.

ProReact Linear Heat Detection (LHD) offers a proven solution. Engineered for continuous monitoring and early warning, our cable-based detection system is ideal for protecting cable trays—whether single-tier, multi-tier, or densely packed.

UL Approved System for Cable Trays

EN Approved System for Cable Trays

ProReact Fixed Activation

Preset alarm temps. Tough cable. Reliable fire safety.

- UL and FM approved

- CE, RoHS, and UKCA certified

- PVC, Nylon or Stainless Steel Braided

.png)

ProReact Fixed Activation (EN)

Preset alarm temps. Tough cable. Reliable fire safety.

- UL and EN approved

- CE, RoHS, and UKCA certified

- LSZH coating, UV stability, and hydrocarbon resistance

- Optional stainless steel braiding for mechanical protection

Why Cable Tray Fire Detection is so Challenging

- Hidden Risks

Electrical faults and overheating often occur deep within trays, out of sight and reach. - Environmental Stress

Dust, humidity, and vibration can interfere with conventional sensors. - Complex Layouts

Multi-tier trays and tight spaces complicate installation and maintenance. - False Alarms

Spot detectors are prone to nuisance alarms in dirty or damp environments.

How ProReact LHD Solves Challenges in Cable Trays

- Continuous Coverage

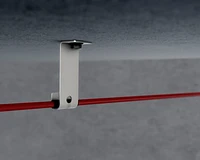

ProReact cables run the full length of the tray, detecting heat anywhere along their path. - Flexible Installation

Use V-Clips, L-Clips, or beam clips to mount cables above or below trays—even in multi-tier configurations. - Resilient Design

With coatings like nylon, PVC, and stainless-steel braid, our cables resist abrasion, moisture, and harsh chemicals - Low Maintenance

Designed as a “fit and forget” solution, ProReact LHD minimizes upkeep and maximizes reliability - Smart Activation Options

- Fixed Temperature (Digital): Triggers at a set temperature—ideal for high-risk zones.

- Programmable Temperature (Analogue): Offers resettable detection and rate-of-rise sensitivity for dynamic environments.

Download the LHD Installation Guide

(PDF, 2.05 MB)

Installation Best Practices for Cable Trays

- For trays up to 0.6m wide: Use a single run of LHD cable centred above the tray.

- For wider trays: Use two runs spaced evenly.

- Cables can be laid directly over other cables or suspended just below the tray using beam clips.

- Protective silicone sleeves are recommended to prevent abrasion from tight zip ties.

Certified to Perform in Cable Trays

ProReact LHD systems are certified to meet global standards, including EN54-28, UL, VdS, CE, and RoHS, ensuring compliance and peace of mind across sectors.